Water Tube Steam Boiler (SJ-W)

Feature

It's for generation of saturated vapor and superheated steam, it fits where bulk pressure and high pressure have the needs the most.

The heat efficiency is high because it's maximized absorption of radiant heat by sufficient and specially-designed combustion chamber.

Because radiant heat loss is minimal with a structure of special membranous wall, the heat efficiency is high and there is no leak of combustion gas.

It can get 99% dry steam by attaching the special anti-priming pipe, extend life span of heat use facilities and plumbing facilities, improve productivity.

It can remove the dust particles by leaving clean space on water tube group.

Cost reduction and productivity was maximized because it's Designed focusing on inexpensive maintenance costs, a high degree of safety.

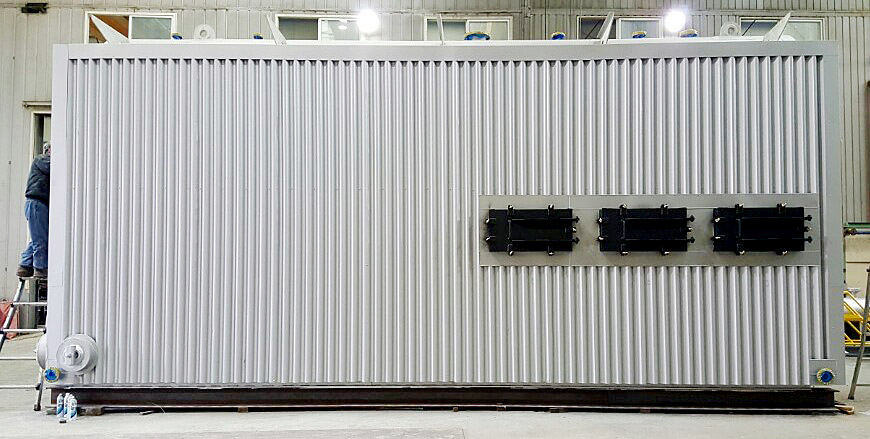

Picture

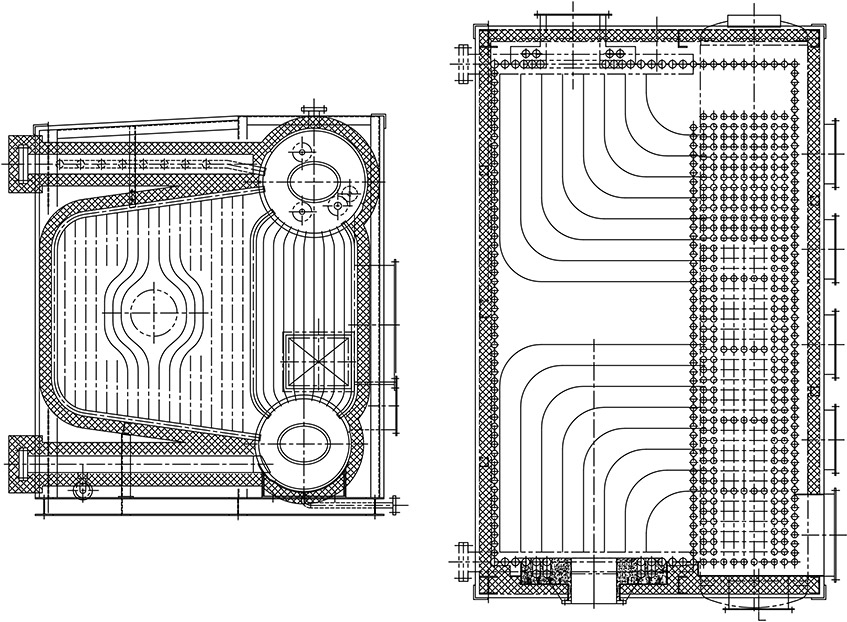

Structure chart

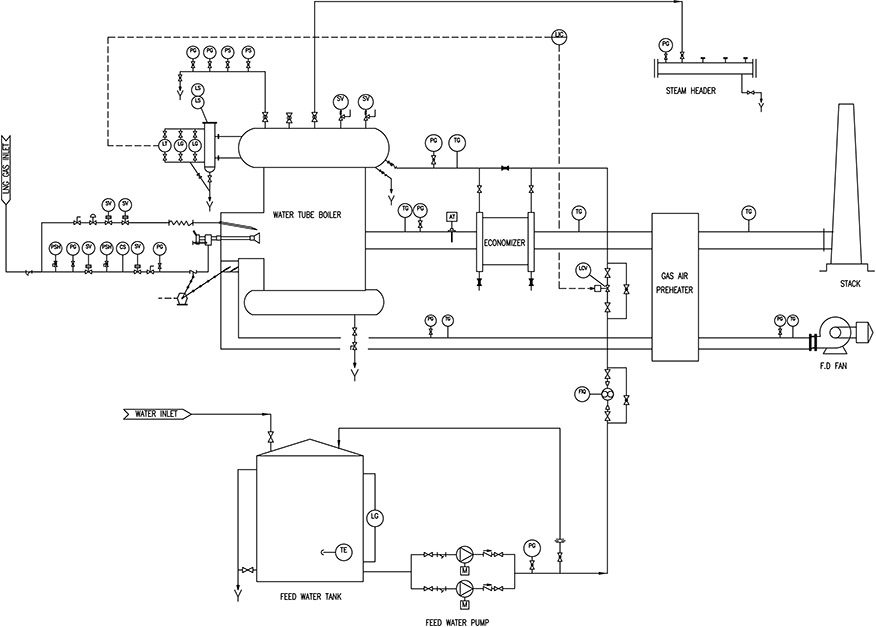

System diagram

Specification

| Item | Model | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2W | 2.5W | 3W | 4W | 5W | 6W | 7W | 8W | 10W | 12W | 15W | 18W | 20W | 25W | 30W | 40W | ||||

| Capacity | ㎏/h | 2,000 | 2,500 | 3,000 | 4,000 | 5,000 | 6,000 | 7,000 | 8,000 | 10,000 | 12,000 | 15,000 | 18,000 | 20,000 | 25,000 | 30,000 | 40,000 | ||

| Oil Consumption | ㎏/h | 149.2 | 186.5 | 223.8 | 298.4 | 372.9 | 447.6 | 522.1 | 596.7 | 745.9 | 895.1 | 1118.9 | 1342.7 | 1491.8 | 1864.8 | 2237.8 | 2983.7 | ||

| Valves | Main | (A)mm | 80 | 100 | 100 | 100 | 125 | 150 | 150 | 150 | 200 | 200 | 200 | 200 | 200 | 250 | 300 | 300 | |

| Safety Valve | (A)mm | 40 | 40 | 40/25 | 40/25 | 40/40 | 40/40 | 50/ 40 | 50/40 | 50/50 | 65/50 | 65/50 | 65/65 | 80/65 | 80/65.2 | 80.2/65 | 100/100 | ||

| Feed Water | (A)mm | 40 | 40 | 40 | 40 | 50 | 50 | 50 | 50 | 50 | 50 | 65 | 65 | 65 | 80 | 80 | 80 | ||

| Drain | (A)mm | 40 | 40 | 40 | 50 | 50 | 50 | 50 | 50 | 50 | 65 | 65 | 65 | 65 | 65 | 65 | 80 | ||

| Level Gauge | inch | 8½ | ← | ← | ← | 11 | ← | ← | ← | ← | 11 | ← | ← | ← | ← | ← | ← | ||

| Burner | Flow Rate | ℓ//h | 60~180 | 70~224 | 90~280 | 100~425 | 130~560 | 160~680 | 165~680 | 165~680 | 180~1080 | 185~1250 | 190~1350 | 190~1850 | 190~1850 | 230~2300 | 270~2700 | 320~3200 | |

| Oil Preheater | ㎾ | 5 | 5 | 5 | 7 | 7 | 9 | 12 | 12 | 15 | 15 | 15 | 20 | 20 | 25 | 30 | 30 | ||

| F.D Fan | Capacity | ㎥/min | 36 | 45 | 54 | 72 | 90 | 108 | 126 | 144 | 180 | 216 | 270 | 324 | 360 | 450 | 540 | 720 | |

| Motor Power | ㎾ | 7.5 | 7.5 | 10 | 15 | 20 | 20 | 25 | 25 | 30 | 40 | 50 | 60 | 75 | 90 | 100 | 130 | ||

| Boiler Weight | ㎏ | 12,200 | 14,100 | 15,600 | 16,200 | 19,600 | 21,800 | 23,600 | 26,500 | 30,500 | 34,200 | 39,400 | 45,000 | 48,000 | 52,000 | 61,000 | 76,000 | ||

| Water Volume | ㎏ | 2,000 | 2,500 | 2,700 | 3,600 | 3,900 | 4,300 | 5,300 | 6,000 | 7,200 | 7,500 | 9,700 | 11,000 | 11,500 | 14,000 | 16,000 | 18,500 | ||

| Stack Diameter | mm | 430 | 460 | 500 | 580 | 650 | 680 | 750 | 820 | 900 | 960 | 1,050 | 1,150 | 1,260 | 1,350 | 1,500 | 1,800 | ||

| Size | Diameter | (Å)mm | 2,400 | 2,560 | 2,750 | 2,435 | 2,505 | 2,605 | 2,790 | 3,000 | 3,035 | 3,215 | 3,360 | 3,450 | 3,550 | 3,860 | 4,060 | 4,600 | |

| Length | (L)mm | 3,850 | 3,950 | 4,200 | 4,255 | 3,815 | 3,955 | 4,200 | 4,350 | 3,538 | 4,395 | 4,920 | 5,200 | 5,310 | 5,310 | 5,400 | 7,200 | ||

| Height | (H)mm | 2,560 | 2,560 | 2,600 | 2,750 | 3,600 | 3,680 | 3,680 | 3,770 | 3,835 | 4,550 | 4,780 | 4,850 | 5,030 | 5,440 | 5,850 | 5,850 | ||

*The above standard specifications can be changed due to product development, etc.