High Efficiency Heating Medium Boiler Built-in Air Preheater (SJ-SE)

Feature

Efficiency of 91% to 95% very high as the world’s first high-efficiency heating medium boiler built-in air preheater.

It doesn't need the separate air preheater, it's possible to install in confined space because of a small footprint.

It's convenient to check, clean and repair because of full open type assembled with bolts in front door.

Even though the boiler stops, there is no dew condensation of air preheater by the latent heat because fireproof adiabatic materials are constructed in the rear inside.

There is no clogging by dust because the fuel gas pass through outside of heating tube and it can be maintain the same lifespan as a boiler because it's easy to clean.

The air preheater can always keep high efficiency state because it's possible to clean in high pressure air or steam or water.

Because hot air is supplied in air-layer outside of the main body when the boiler restarts, It can always maintain high combustion efficiency, no radiant heat loss and tidy appearance due to no air duct.

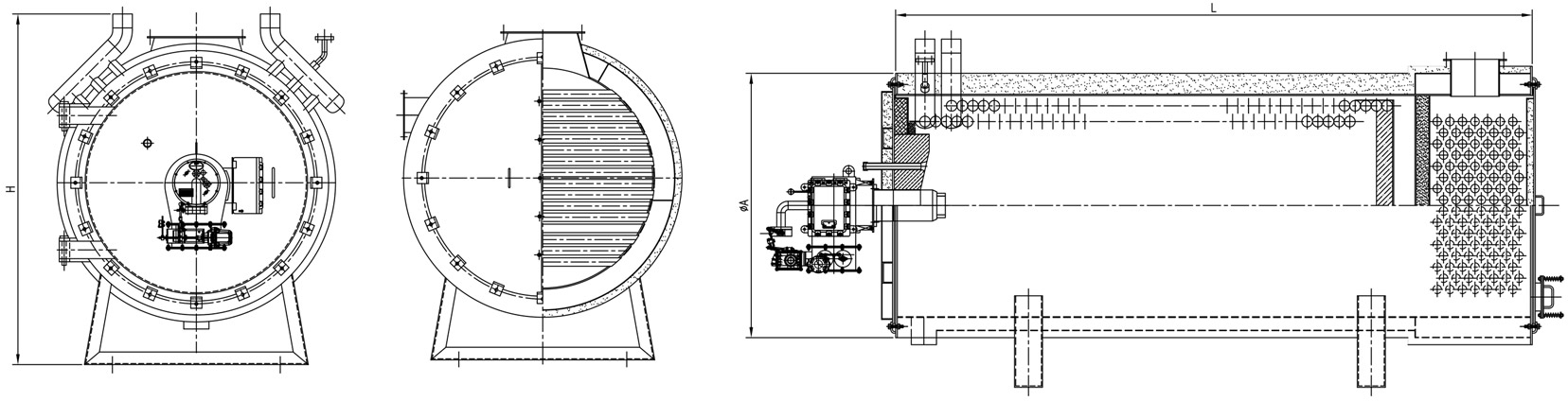

Picture

SE-1

SE-2

Structure chart

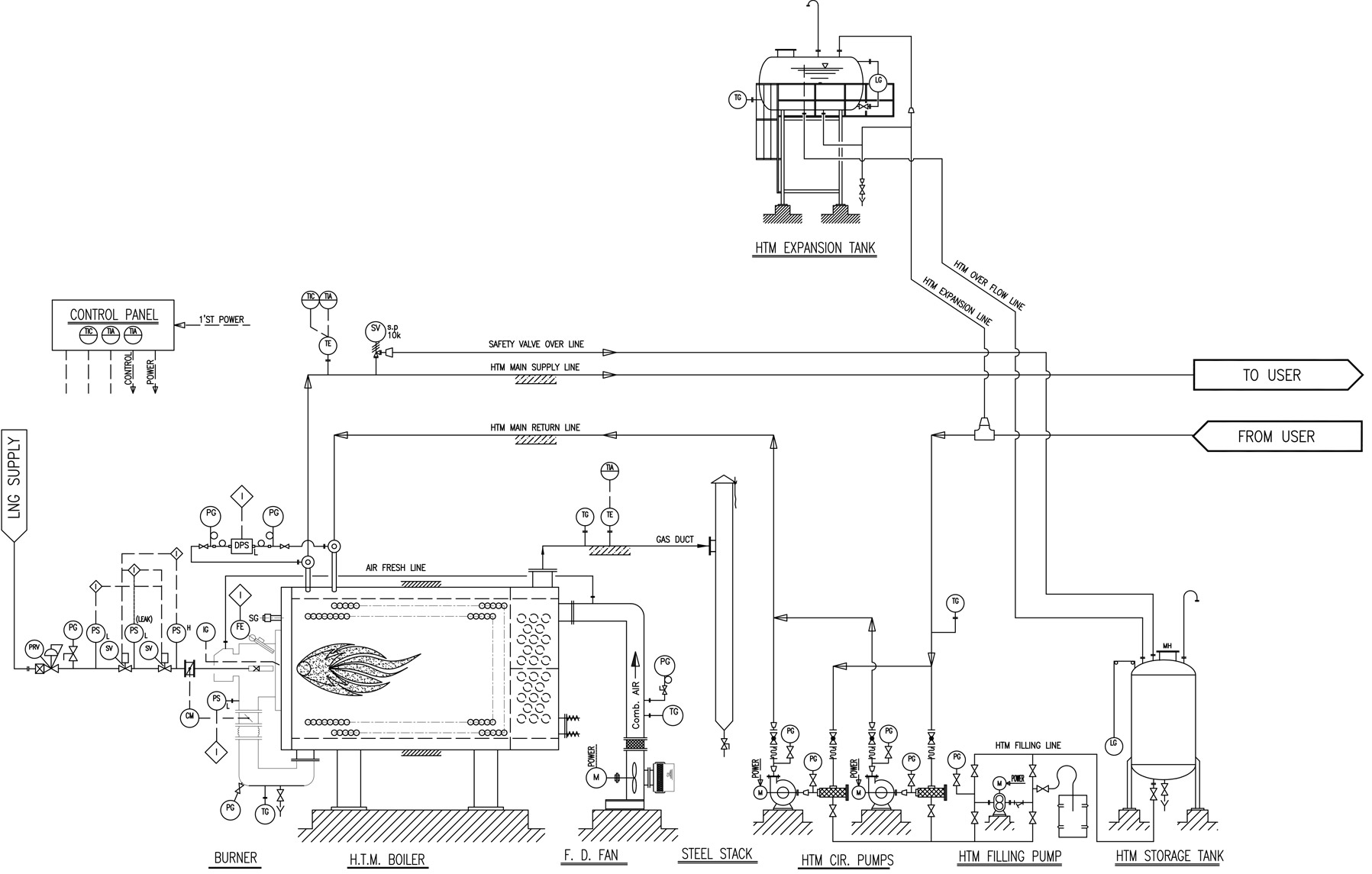

System diagram

Specification

| Item | Model | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 30SE | 40SE | 50SE | 60SE | 80SE | 100SE | 120SE | 150SE | 200SE | 250SE | 300SE | 350SE | 400SE | 500SE | 600SE | 800SE | |||

| Capacity | 10⁴㎉/h | 30 | 40 | 50 | 60 | 80 | 100 | 120 | 150 | 200 | 250 | 300 | 350 | 400 | 500 | 600 | 800 | |

| Max. Operating Pressure | ㎏/㎠g | ← | ← | ← | ← | ← | ← | ← | ← | ← | ← | ← | ← | ← | ← | ← | ← | |

| Max. Operating Temperature | ℃ | ← | ← | ← | ← | ← | ← | ← | ← | ← | ← | ← | ← | ← | ← | ← | ← | |

| Fuel Consumption |

Oil | ㎏/h | 33.8 | 45.1 | 56.4 | 67.6 | 90.2 | 112.7 | 135.2 | 169.1 | 225.4 | 281.8 | 338.1 | 394.5 | 450.8 | 563.5 | 676.2 | 901.6 |

| Gas | N㎥/h | 34.6 | 46.1 | 57.7 | 69.2 | 92.2 | 115.3 | 138.4 | 173.0 | 230.6 | 288.3 | 345.9 | 403.6 | 461.2 | 576.5 | 691.8 | 922.4 | |

| In-Out Header | (A)mm | 65/ 65 | 65/ 65 | 65/ 65 | 65/ 65 | 100/ 100 | 100/ 100 | 125/ 125 | 125/ 125 | 150/ 150 | 150/ 150 | 200/ 200 | 200/ 200 | 200/ 200 | 250/ 250 | 250/ 250 | 300/ 300 | |

| Circulation Pump |

Flow Rate | ㎥/h | 24 | 32 | 40 | 48 | 64 | 80 | 96 | 120 | 160 | 200 | 240 | 280 | 300 | 400 | 450 | 600 |

| Total Head | mH | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 60 | 60 | 60 | 65 | |

| Motor Power |

㎾ | 7.5 | 11 | 11 | 15 | 15 | 15 | 19 | 22 | 30 | 37 | 45 | 56 | 75 | 90 | 100 | 150 | |

| Empty Volume | Lit | 240 | 360 | 450 | 550 | 740 | 960 | 1,040 | 1,290 | 1,640 | 2,460 | 3,150 | 3,690 | 4,120 | 4,600 | 5,250 | 7,380 | |

| Boiler Weight | ㎏ | 2,500 | 3,500 | 4,300 | 4,900 | 6,000 | 6,500 | 7,500 | 8,500 | 11,000 | 12,000 | 12,500 | 18,000 | 22,000 | 25,000 | 28,000 | 33,000 | |

| Stack Diameter | mm | 250 | 300 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 750 | 850 | 900 | 1,000 | 1,100 | 1,300 | |

| Size | Diameter | (Å)mm | 1,280 | 1,350 | 1,410 | 1,450 | 1,490 | 1,620 | 1,740 | 1,890 | 2,030 | 2,160 | 2,400 | 2,640 | 2,700 | 2,900 | 3,200 | 3,600 |

| Length | (L)mm | 2,500 | 2,750 | 2,800 | 2,800 | 3,250 | 3,650 | 4,000 | 4,400 | 4,850 | 5,550 | 6,250 | 6,500 | 6,800 | 7,000 | 7,600 | 8,600 | |

| Height | (H)mm | 1,700 | 1,760 | 1,820 | 1,820 | 2,000 | 2,050 | 2,150 | 2,270 | 2,400 | 2,700 | 2,850 | 2,890 | 2,950 | 3,150 | 3,500 | 3,900 | |

*The above standard specifications can be changed due to product development, etc.